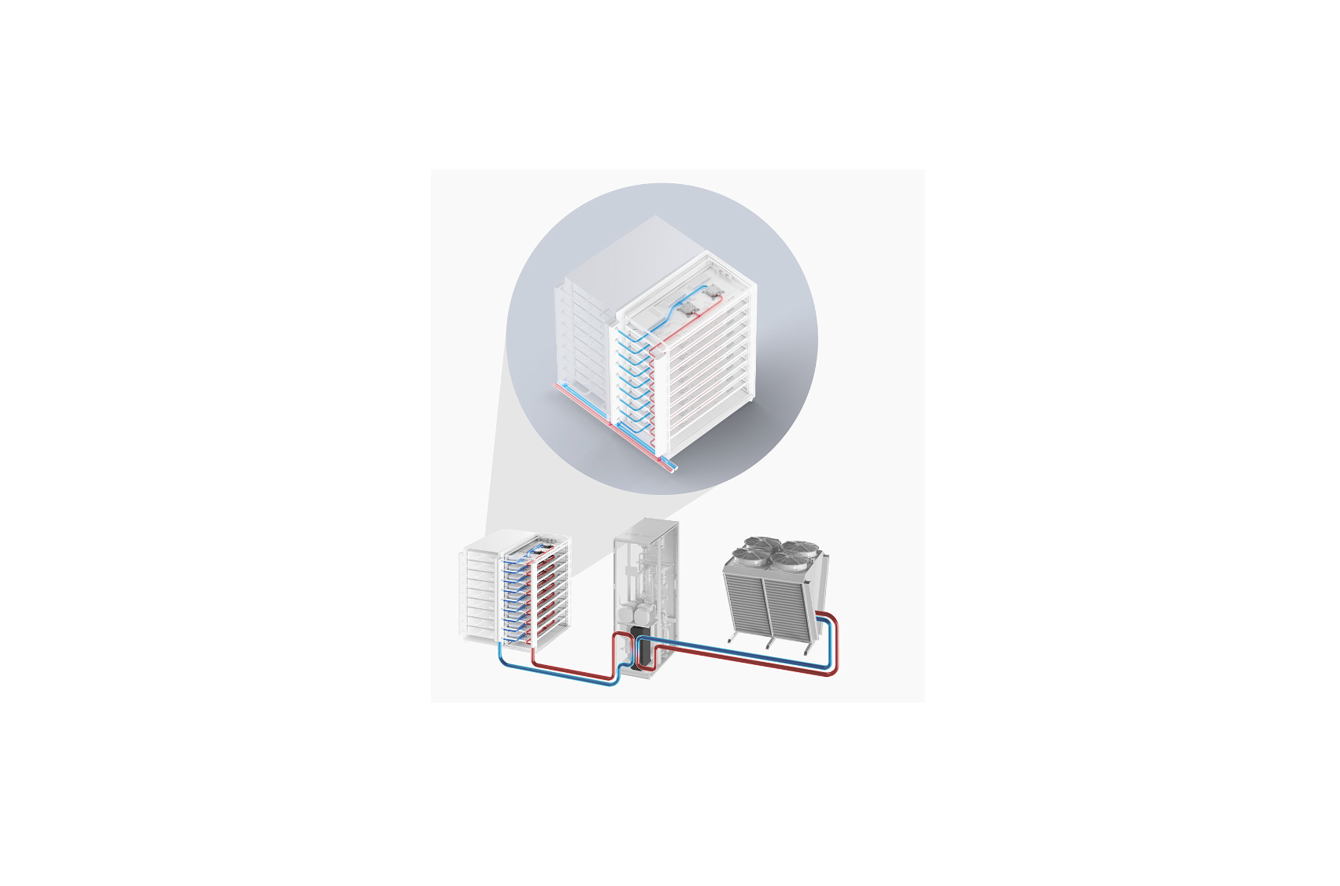

Heat Core’s Hydro Cooling Core Technology:

Direct Liquid Cooling

This system adopts Direct Liquid Cooling (DLC) technology, specifically using cold plate hydro cooling. Water is used as the heat transfer medium, circulating through internal channels within cold plates that are directly attached to heat-generating components such as chips. The coolant absorbs heat through thermal conduction and transfers it away to external cooling infrastructure. In DLC systems, the liquid does not come into direct contact with electronic components; instead, heat is efficiently removed via the cold plates, ensuring safe and effective thermal management.Water has a higher specific heat capacity than immersion oil and air, allowing it to absorb more heat per unit mass. This makes it highly efficient for thermal management in electronic system.

Advantages of Hydro Cooling:

A Comparison with Air and Immersion Cooling

1. High Specific Heat Capacity

Water has a higher specific heat capacity than immersion oil and air, allowing it to absorb more heat per unit mass. This makes it highly efficient for thermal management in electronic system.

2. Low Operational Noise

The M6X series hydro cooling system significantly reduces mining farm operational noise. It leverages variable frequency technology to minimize the noise generated by pumps and fans, and also offers customizable noise reduction solutions.

3. Low Failure Rate, High Uptime The M6X series offers high reliability, with a 40% power derating margin, allowing for flexible responses to cryptocurrency price fluctuations and significantly extending miner lifespan. Its efficient hydro cooling design ensures stable operation in high-temperature, humid, vibrating, and dusty environments, greatly reducing failure rates.

4. High-Temp Water Outlet for Lower Costs

Whatsminer's unique high-temperature water outlet design significantly reduces the investment and operational cost of the cooling system. By enabling the use of water-free dry coolers and allowing stable operation in ambient temperatures up to 60°C, it minimizes water and electricity consumption. Moreover, higher water temperatures broaden the scope for heat reuse in applications such as residential heating, industrial and agricultural use, and seawater desalination.

5. High Power Density & Reduced Opex

Up to 10kW of each hydro miners make the quantity of total units only 1/3 of air or immersion miners, Cooperate with Heat Core’s effiient water cooling system which reduces overall Opex(operational expense) at least 2/3 compare to air or immersion miners.

Total Cost of Ownership:

Why Hydro Cooling Wins

Unlike traditional systems, HC hydro cooling uses a closed-loop dry cooler, eliminating the need for evaporative water systems and complex on-site infrastructure. This not only reduces installation and maintenance costs but also minimizes downtime and failure rates—delivering the lowest total cost of ownership over time.

We Align with ESG Standards

1. Supporting Environmental, Social, and Governance Goals Our hydro cooling solution fully supports ESG principles by promoting cleaner, more sustainable technology. Through sustainable design and responsible operation, we actively reduce environmental impact and help drive positive social and governance outcomes.

2. Zero Water Consumption for a Sustainable Future With water scarcity rising worldwide, our system’s dry cooler design eliminates evaporative water use—requiring zero water consumption during operation. This protects valuable freshwater resources, reduces costs, and aligns with global efforts toward environmental sustainability.

All of our products and solutions are built on hydro cooling technology. As a pioneer in zero-water-consumption innovation, HeatCore is committed to shaping the sustainable future of high-performance computing.

Comments