E Series

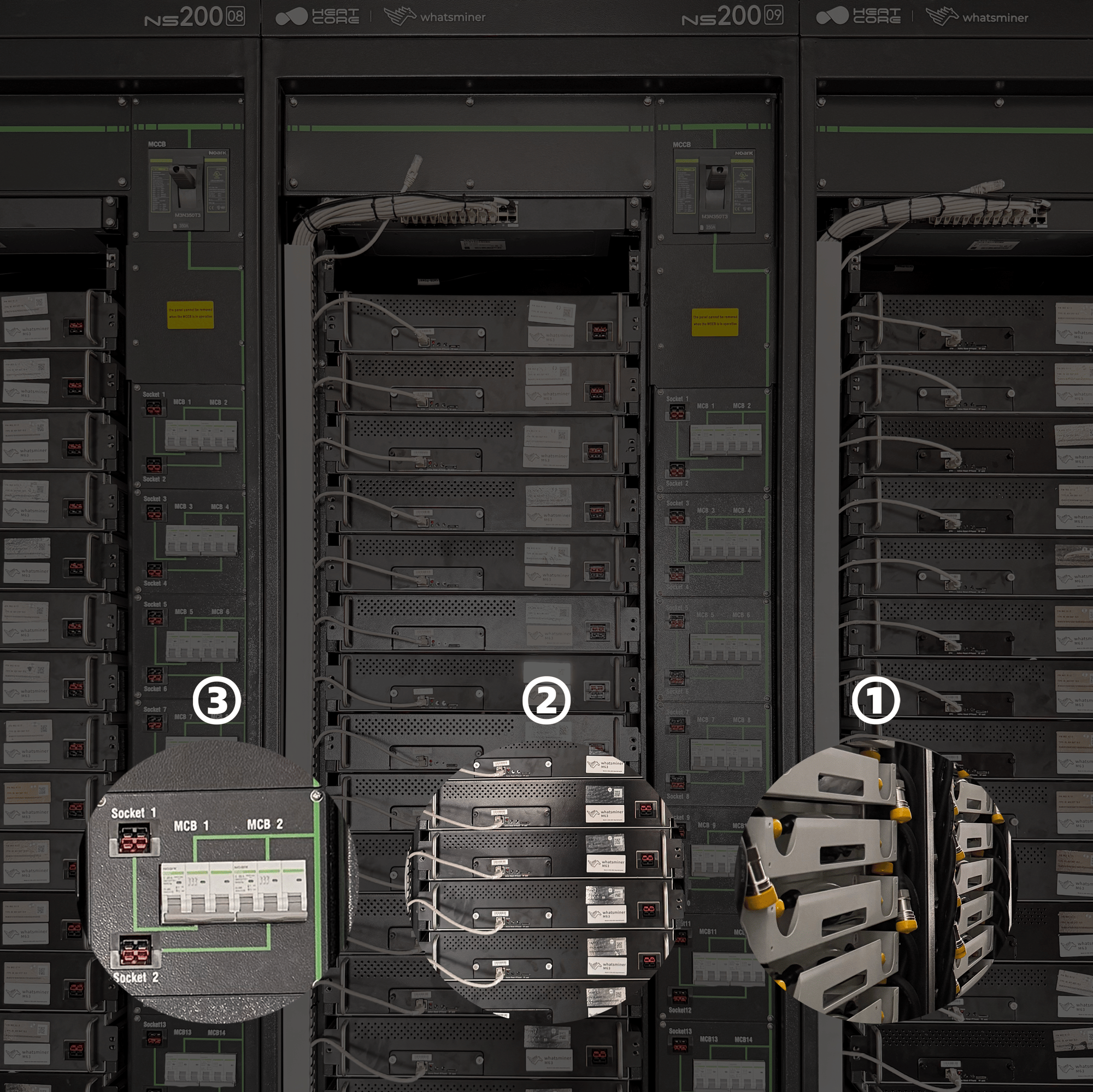

RACK

① Manifold & Quick Connector (female)

② PDU

③ Server Slots (Including 1U space for access layer swtich)

Scalability & High-Density Space

It features a modular design for easier production, repair, and future expansion.

Each Rack integrates 2U Server Slots, PDU, Manifold, Switch, and supports up to 20 servers.

Premium Quality for Reliability

With the rack constructed from Q235 steel, manifold from 304 Stainless steel, branch hoses from EPDM material, the it rack is designed for premium high strength and corrosion- resistance.

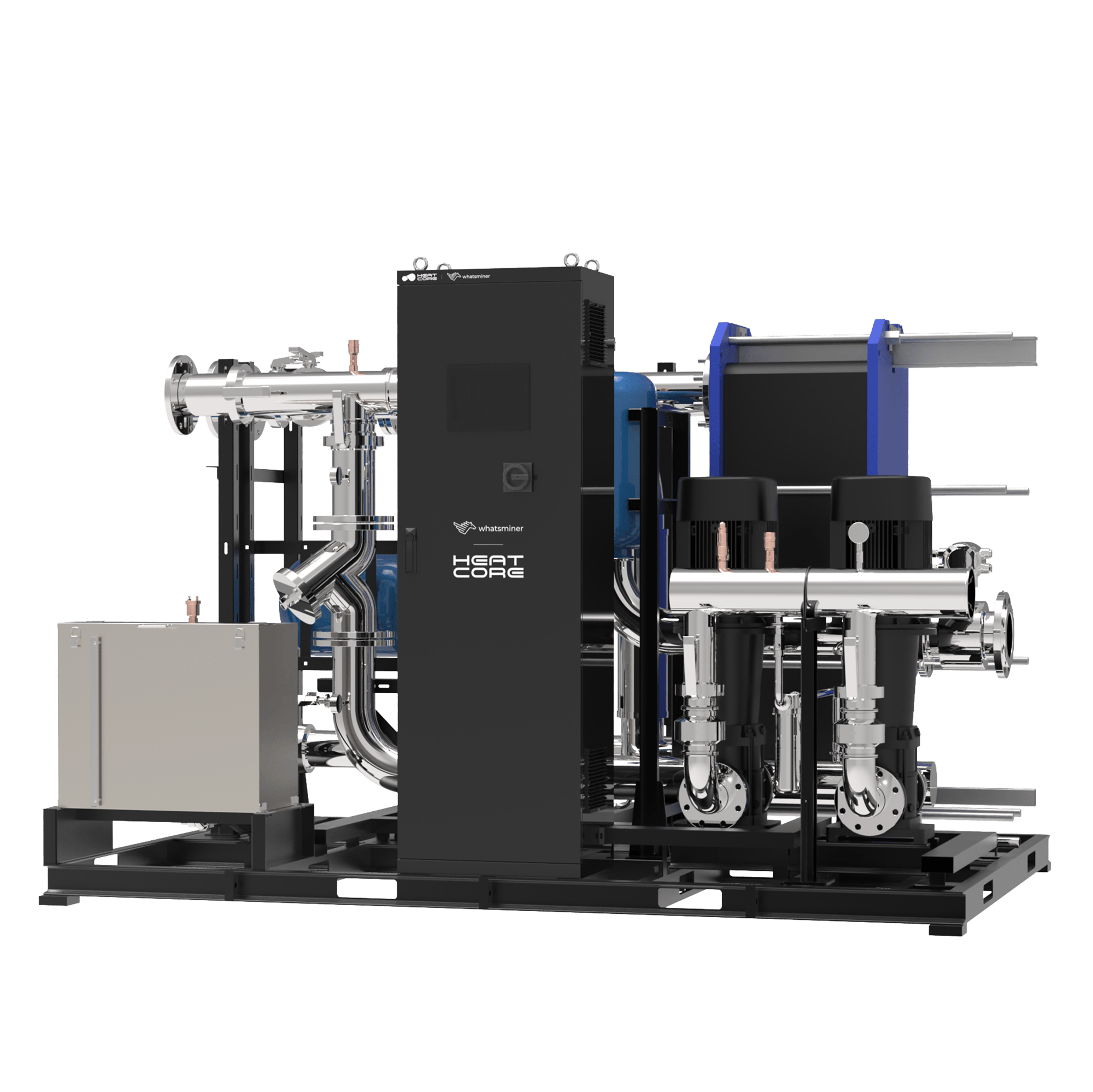

CDU

① Coolant Distribution Unit (pump, expansion tank, filling tank, air vent valve, sensors, Y Strainer etc)

Stable Thermal & Pressure Control

Innovative PLC-based control logic ensures automatic coolant replenishment, temperature fluctuation (within ±2℃) and supply-return pressure difference (within 1.0 bar) control, guaranteeing stable server operation.

O&M with Visibility & Serviceability

With the touchscreen HMI(Human Machine Interface ) and HeatCore Cloud, operators could have easy access to set critical data(pressure difference, target temperature, pump), monitor the trend curve , get notified for the alarms.

Zero-Downtime Maintenance

Hot-swappable components and online maintenance design Y-strainer ensure stable operation and easy upkeep, reducing the risk of interrupting services.

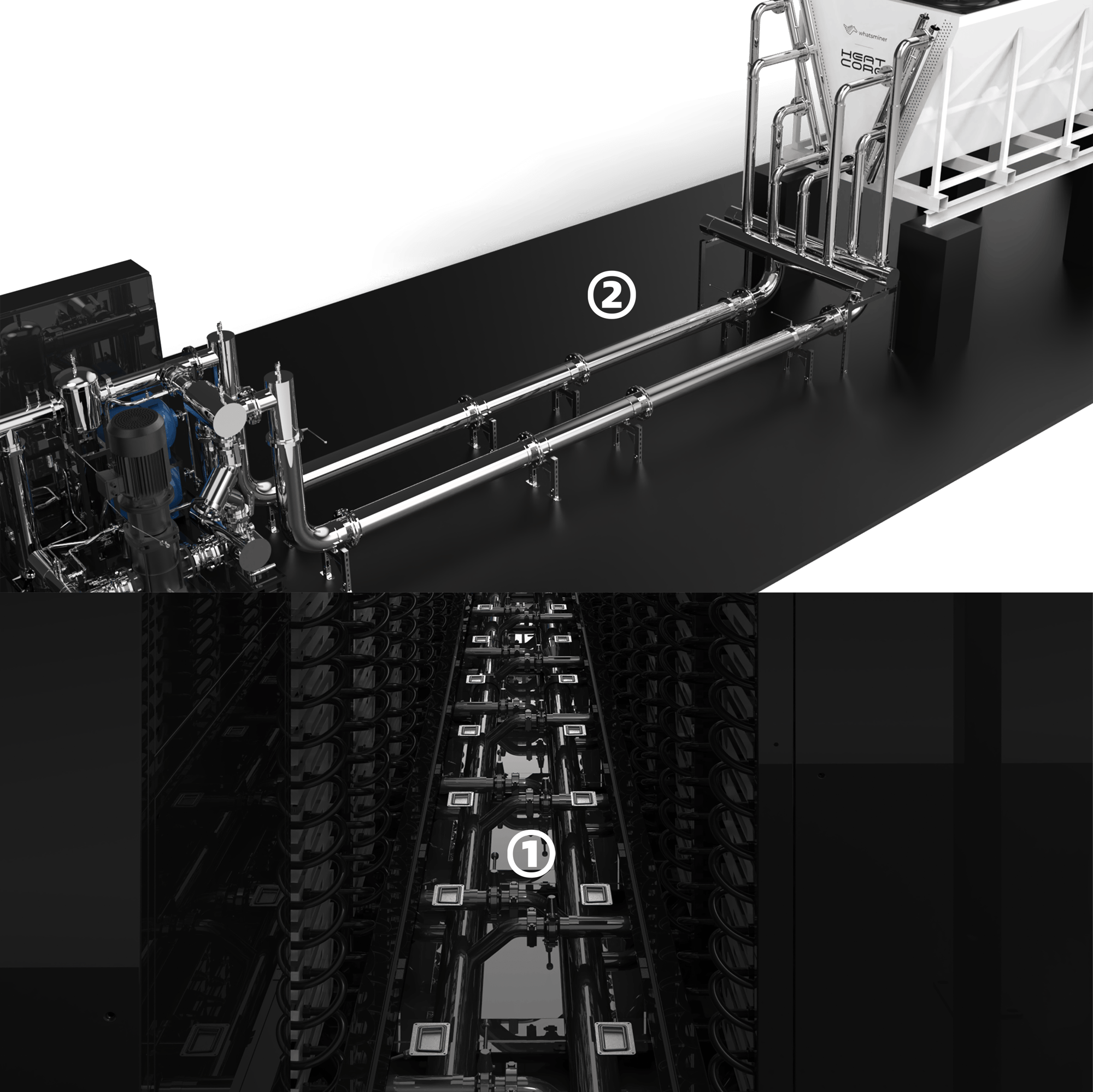

CONNECTION PIPELINE

Connection Pipeline Including:

① Connection Between CDU and Server Rack

② Connection Between CDU and Dry Cooler

Piping: Prefabricated High Quality Material & Reliable Design

The main pipeline is constructed with sanitary-grade 304 stainless steel. Fluid simulation analysis is applied to ensures uniform flow distribution across branches.

Space-Optimized Layout

With connection pipelines installed beneath the N-Racks, and copper busbars above, it maximize space efficiency, reduces the risk of contact between electrical and water systems. uniform flow distribution across. branches

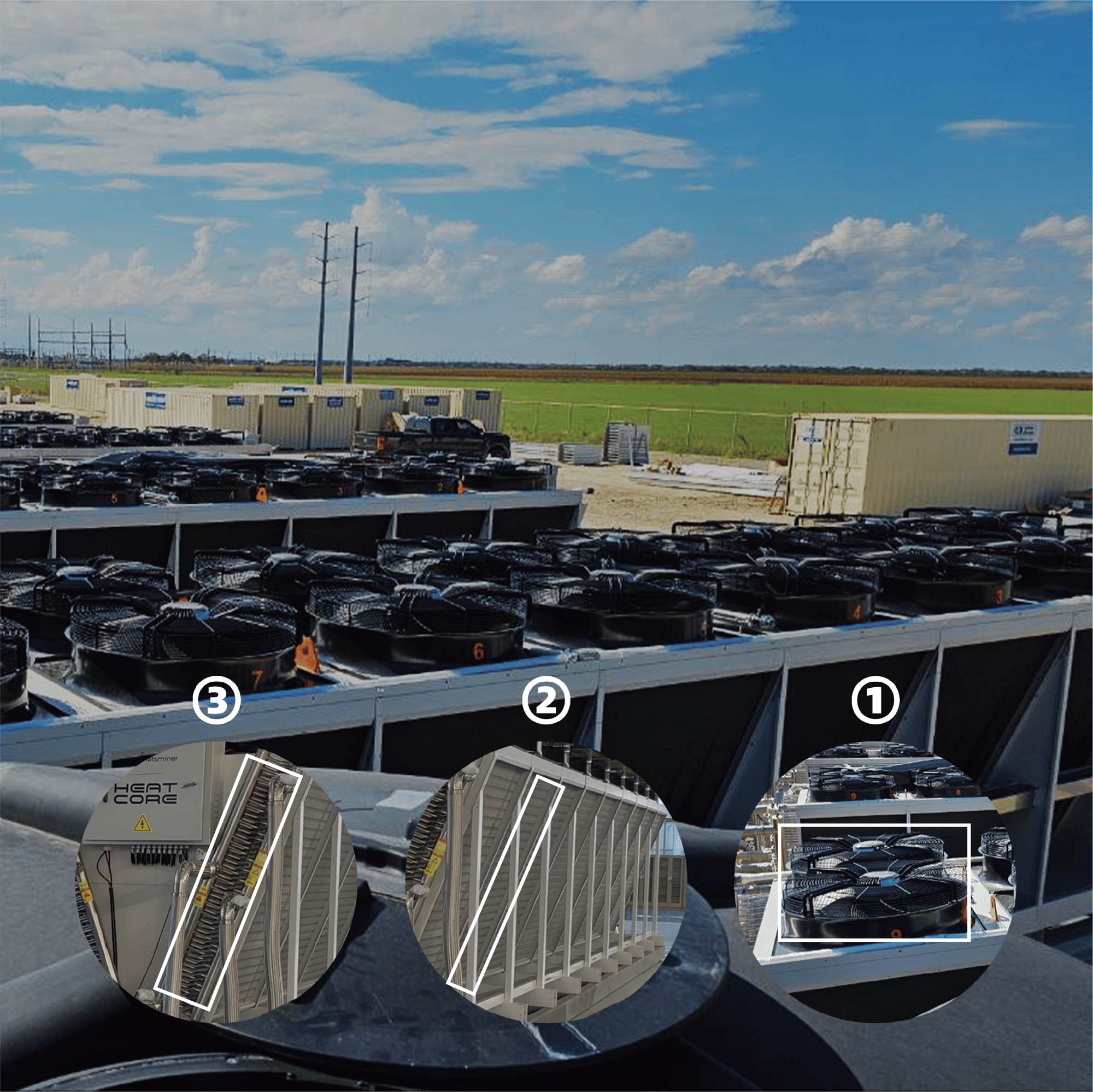

DRY COOLER

① Fans

② Fins

③ Coil Tube

Zero or Reduced Water Consumption

Environmentally sustainable and ideal for regions with water scarcity or strict regulations.

Corrosion-Resistant Structure Design

Constructed with high-grade Type 304L stainless steel tubing and aluminum fins as standard.

Broad Adaptability

Fully custmized solution to meet the needs of diverse climates, with intelligent control systems that auto-adjust to environmental changes for stable operation all year round. round independent electrical protection.

OTHER KEY INFRASTRUCTURE

① Power supply (main switchboards with ACB, power meter integrated)

② Leakage Detection system

③ Lightning protection and grounding system

④ Network system

In additon to CDU and hydro server rack, the container also integrates other key infrastructure like network switches, leakage detection system, main switchboards (for power distribution to server rack, and CDU, eliminating individual cabling one rack by one rack, simplifying installation),

This Pre-fabricated and pre-tested systems also ensure reliability and reduce the risk of installation errors, enhancing operational stability.

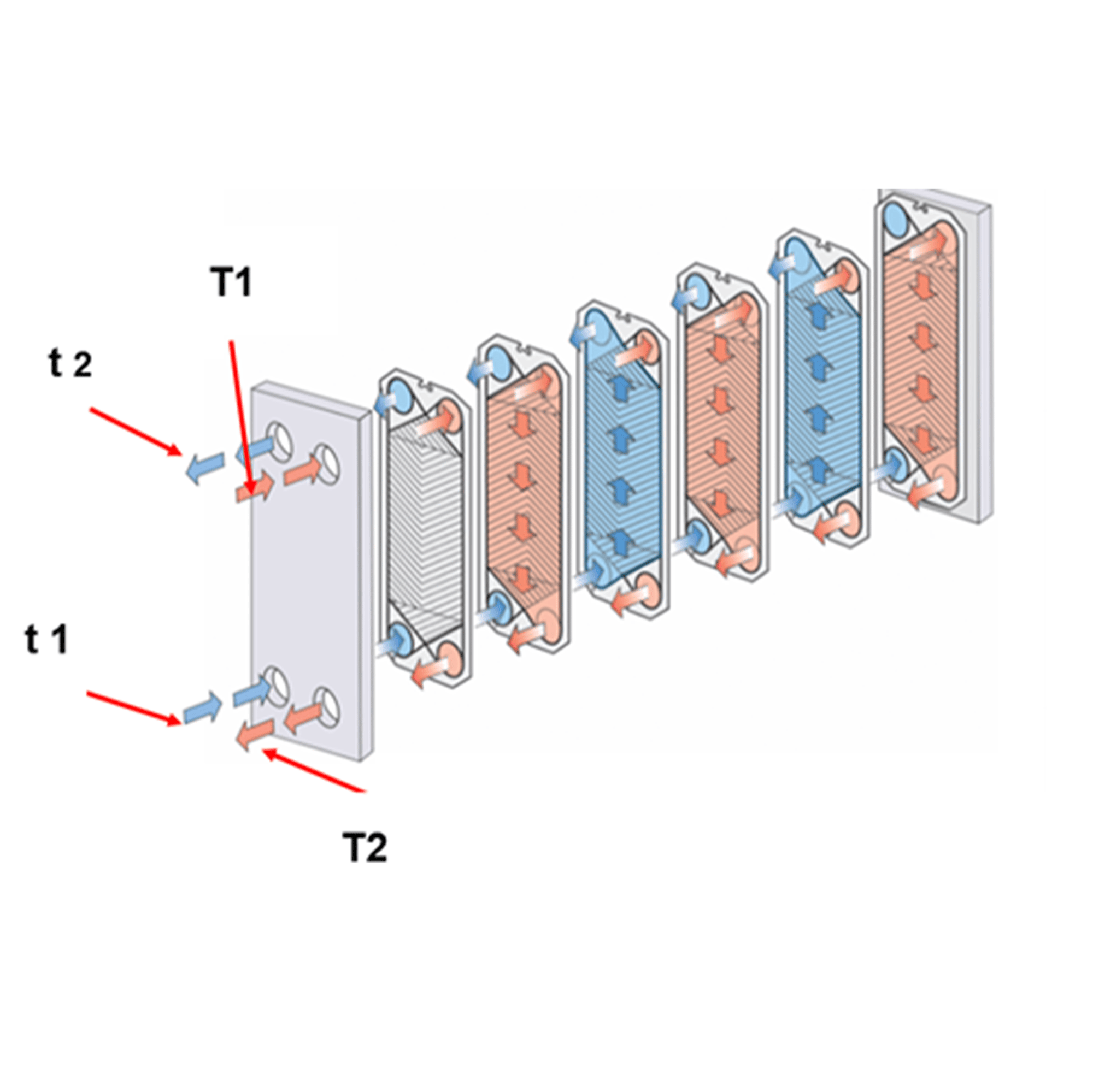

PHE(OPTIONAL)

① Plate Heat Exchnger

We would support customization case by case with precision and efficiency.

With the outlet water temperature of up to 80°C, significantly higher than the industry average, our system is an ideal choice for various heat utilization applications, including but not limited to agricultural heating, residential heating, and industrial process.

The Plate Heat Exchanger provided by HeatCore could efficiently transfers heat, between hot fluid from hydro servers and cold fluid from external systems via metal plates, ensuring optimal performance.

Rack

CDU

Connection Pipeline

Dry Cooler

Other Key Infrastructure

PHE(optional)

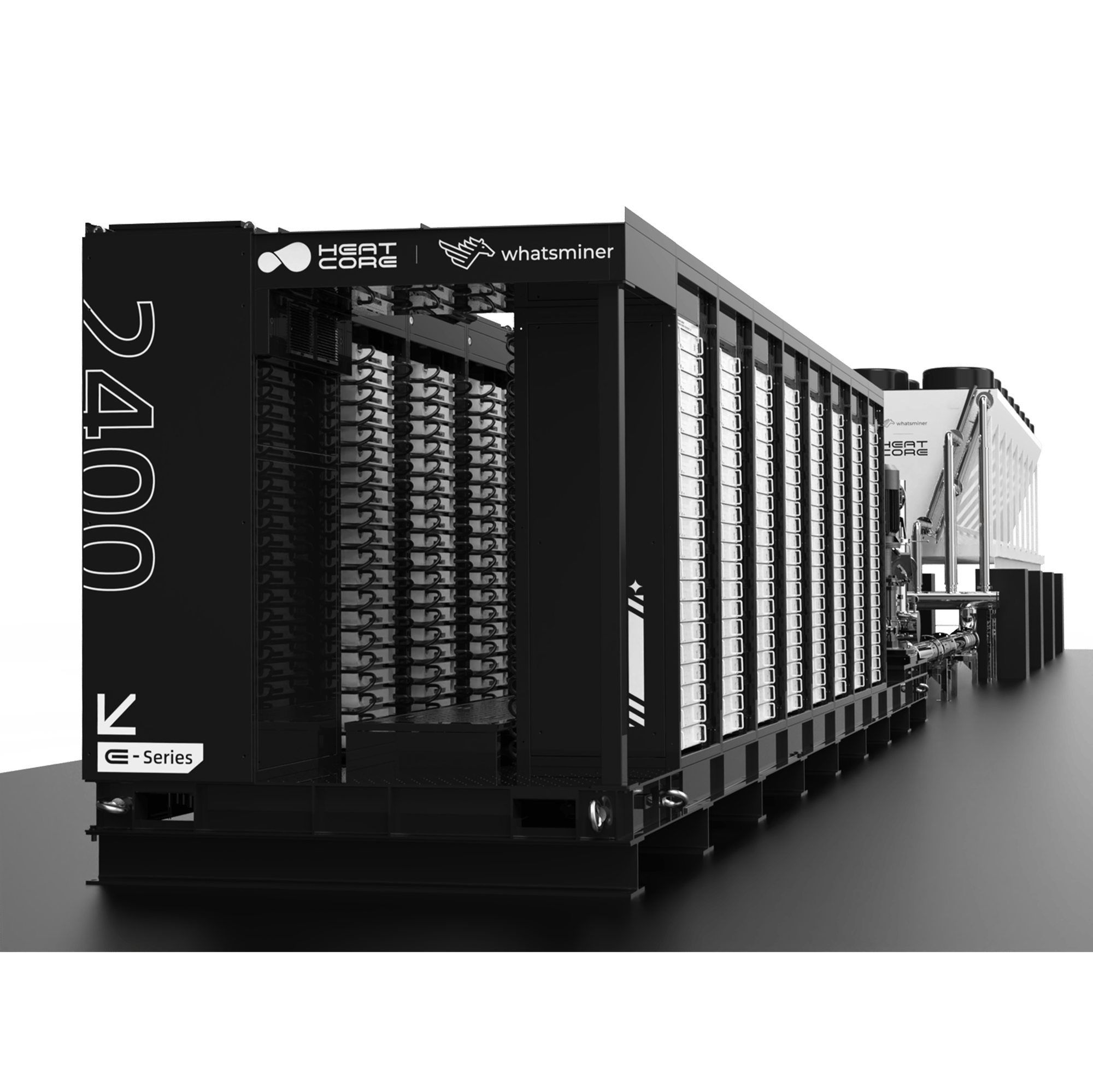

E Series

E stands for easy deployment. Compared to rack system, it is designed for indoor operation while integrating all components like the containerized solution. Each module supports a power capacity of up to 3.6MW.

Indoor Rapid Deployment

Key components including CDU, pipeline, IT Rack, electrial, network systems are pre-assembled in a single unit, supporting rapid & hassle-free indoor deployment.

Energy-Saving Design

Capable of supporting up to 20 Whatsminer servers per rack with hydro-cooling, achieving a low PUE (<1.05), zero water consumption, minimal noise, and reduced energy expenses

Safety & Compliance

Features customizable UL/CSA/NEC/CE-compliant components and a 3-inch tilt drainage system to prevent fluid leak damage

Friendly O&M

The system has automatic thermal and pressure control mechnism, along with local HMI, and Heat Core Cloud, achieving unattended and minimal-staff operation.

Compared to air cooling mining site, lower-noise circulating pump also improves O&M comfort

E Series

Experience the ES Series Indoor Solution

Each setup includes 10–12 hydro server rack, and every rack runs 20 WhatsMiner M63 miners.

With modular design and adaptive control, ES offers real-time monitoring, energy management, and easy remote maintenance.

ABOUT ES2400 ↘

ES2400 SPECIFICATION

| CATEGORY | DETAILS | ||

| Model | ES2400 | ||

| Container‘s Capacity | 240 units of M53/M63/M65 Series Miners | ||

| Main Components Included | Smart Control System(CDU)/Switchgear/12*IT Rack/Dry Cooler | ||

| Size | 9815x2200x2330mm(Fit to 40ft-HQ container) | ||

| Container‘s Net Weight/Operating Weight | 12500kg/22500kg | ||

| Input Power | 3-Ph/PE 380-480V 50/60Hz | ||

| Max. Power Consumption | 2490kW | ||

| Max. Output Temperature | 80°C(176 °F) (after plate heat exchanger, up to 75°C/ 167 °F) | ||

| Thermal Efficiency | 95% | ||

| Heat Exchangers | Customized on Demand |

||

| Dry Coolers | Customized on Demand | ||

| Pipe System | Customized on Demand |

||

| Electrical Code for the US | NFPA 70, UL508A, UL2755, UL50E, UL891 | ||

| Electrical Code for the EU | IEC 61439, IEC 60204 | ||

| Certification | CE or CSA Field Evaluation | ||

| Note: Customizable Design According to Specific Requirements | |||

ES Series Loading & Unloading

LOADING:

Forklift Lifting → Component Securing → Secure Placement → Loading Certification

UNLOADING:

Controlled Forklift Unloading → Removal of Securing Components → Site Preparation → Commissioning

Notes :

1.The hydro cooling system and dry cooler could be placed on level ground. The ground should be hardened to support a minimum load of 35 tons to ensure stability.

2.Suitable for altitudes ≤2000 meters. For altitudes above 1000 meters, account for a capacity reduction of approximately 1% for transformers and switches per additional 100 meters.

3.Operates in temperatures from −25 to 45 °C (−13 to 113 °F) and relative humidity of 10%RH to 85%RH(non-condensing).

4.The ambient temperature of the HeatCore hydro cooling system does not equate to the Whatsminer M6X hydro server’s operating environment temperature.

5.Liquid coolant is pure water (or distilled water)+ special corrosion inhibitor, In environments below 0 °C (32 °F), consider antifreeze(select a ratio according to a freezing point).

6.Regular maintenance and inspections are required to prevent corrosion or scaling, extending equipment lifespan.

7.Ensure at least 4-6 meters of air inlet space on both long sides of the dry cooler to maintain efficient heat dissipation.

8.Coolant volume, regarding hydro cooling system, for instance ES2000 + DC2000 (200 servers) , ES2400 + DC2400 (240 servers) , the required coolant volume is approximately 2,300L to 2,500L.

9.PUE stands for Power Usage Effectiveness, defined as the ratio of total hydro cooling system's energy consumption to IT server load energy usage.

10.Normally, lower PUE (closer to 1) indicates better energy utilization, reducing operational costs. The PUE of HeatCore's hydro cooling is less than 1.05.

For instance, in ES2000 (200 servers) + DC2000, the non-IT support components like CDU pumps, dry cooler fans, PLC, consume less than 100kW.

11.Flexible configuration, the qty of server slots and server racks within the ES skid system could be customized based on site power availability and transformer (or generator) capacity.

Something Powerful

Tell The Reader More

The headline and subheader tells us what you're offering, and the form header closes the deal. Over here you can explain why your offer is so great it's worth filling out a form for.

Remember:

- Bullets are great

- For spelling out benefits and

- Turning visitors into leads.

ES 2400

ES 2400 SPECIFICATION

| Category | Details |

| Model | HS05 |

| Rack Capacity | 1 Unit M64 series |

| Main Components Included | Smart Control System(CDU), PDU, etc. |

| Dimensions (L x W x H)-mm | 480*600*545 |

| Dimensions(without dry cooler) (W x D x H)-mm | |

| Net Weight/Operating Weight-kg | 35 kg/ 50 kg |

| Net Weight/Operating Weight(without dry cooler)-kg | |

| Input power | Single Ph/N/PE 200-240V 50/60Hz |

| Max Power Consumption | 6 kw |

| Maximum output Temperature | |

| Thermal Efficiency | 95% |

| No. of heat exchanger | 2 |

| Electrical Code for the US | |

| Electrical Code for the EU |

E SERIES

E means Easy deployment. Compare to rack system, it design for indoor operation but like container integrated everything together. Each single module can up to 3.6Mw.

E SERIES: ES 2400

Indoor Rapid Deployment

Pre-assembled CDU, IT rack, electrical, and network systems in a 40HQ/20FT container allow for fast indoor deployment without requiring new infrastructure

Energy-Saving Design

Capable of supporting up to 20 Whatsminer servers per rack with hydro-cooling, achieving a low PUE (<1.05), zero water consumption, minimal noise, and reduced energy expenses

Safety & Compliance

Features customizable UL/CSA/NEC/CE-compliant components and a 3-inch tilt drainage system to prevent fluid leak damage

Smart Operations & Maintenance

PLC control ensures ±2°C temperature stability, 1.0 bar pressure, dual power supply, anti-condensation, leak detection, and overpressure protection.

ES 2400

| Category | Details |

| Model | HS05 |

| Rack Capacity | 1 Unit M64 series |

| Main Components Included | Smart Control System(CDU), PDU, etc. |

| Dimensions (L x W x H)-mm | 480*600*545 |

| Dimensions(without dry cooler) (W x D x H)-mm | |

| Net Weight/Operating Weight-kg | 35 kg/ 50 kg |

| Net Weight/Operating Weight(without dry cooler)-kg | |

| Input power | Single Ph/N/PE 200-240V 50/60Hz |

| Max Power Consumption | 6 kw |

| Maximum output Temperature | |

| Thermal Efficiency | 95% |

| No. of heat exchanger | 2 |

| Electrical Code for the US | |

| Electrical Code for the EU |