Direct Liquid Cooling

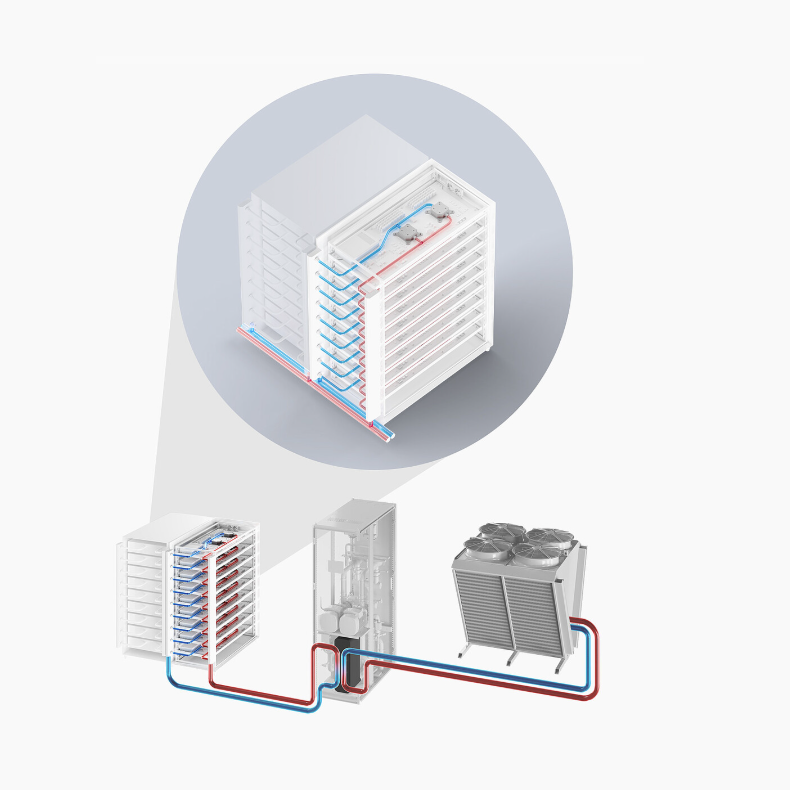

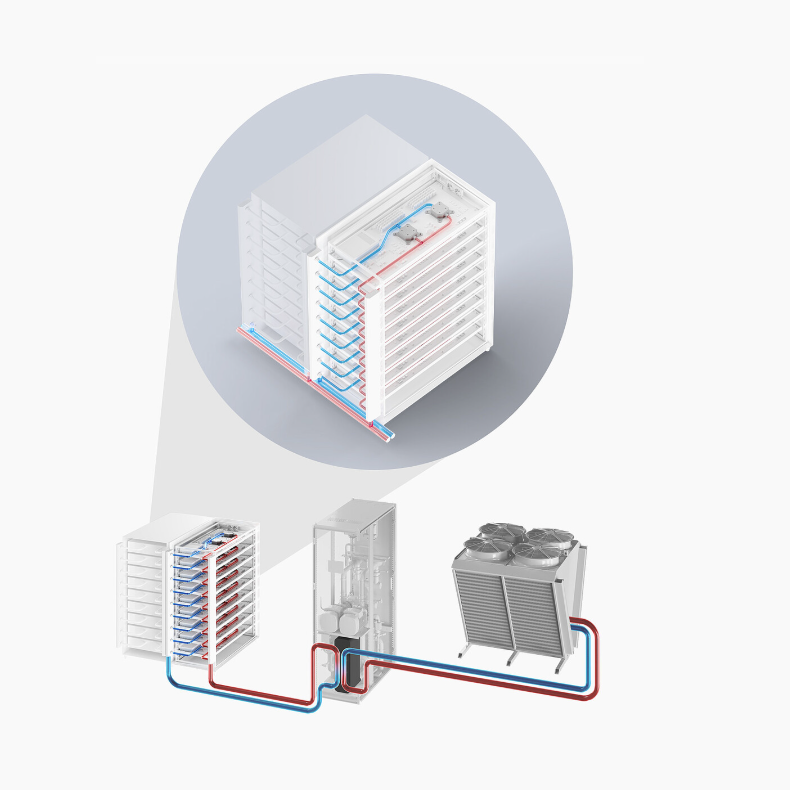

Direct Liquid Cooling (DLC) works by circulating a liquid coolant—such as water or non-conductive fluids through specially designed cold plates or heat sinks that are in direct contact with the hardware. The liquid absorbs the heat and carries it away to an external heat exchanger or dry cooler, where it is dissipated into the environment or repurposed for secondary uses, such as heating nearby facilities. This method is far more efficient than air cooling, offering higher thermal conductivity, lower energy consumption, and a significantly reduced carbon footprint.

This results in much higher rack density, high PUE(<1.03) and allowing compact system designs without compromising performance.

Sanitary Stainless Steel Pipe System

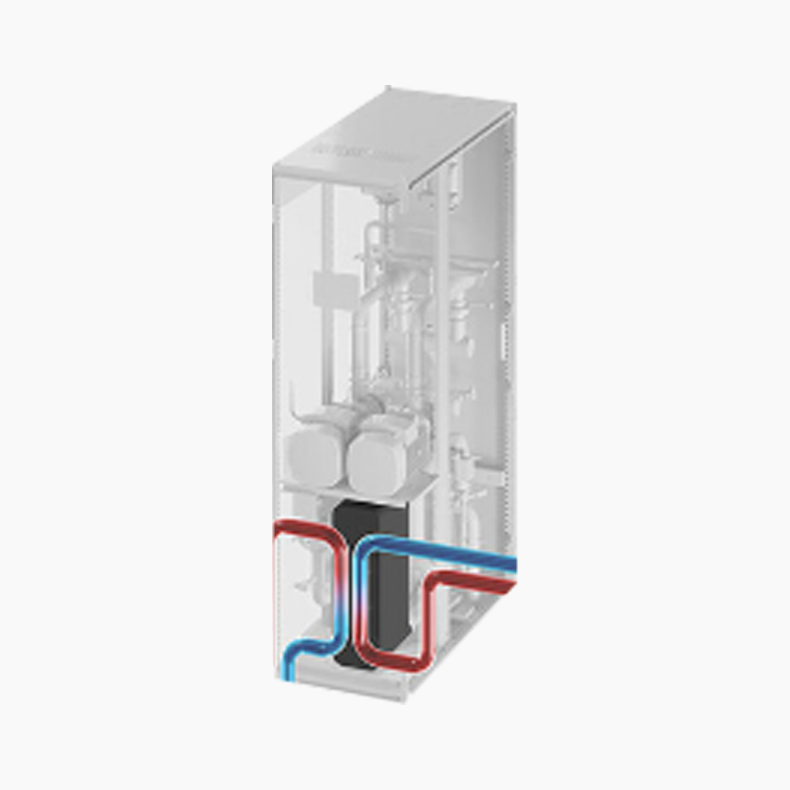

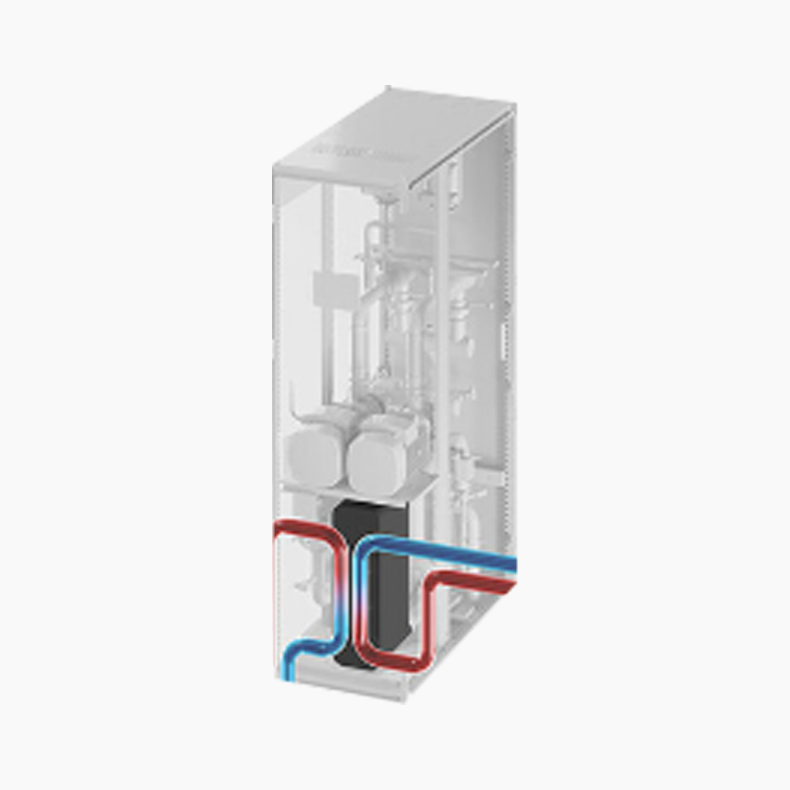

Data centers uses standard CDU(Coolant Distribution Units, in Heat Core we call it Smart Control System). It loses flexibility. The Coolant Distribution Units (CDU) use the Smart Control System to intelligently manage the centralized pumping system that cools multiple racks and ensures target flow and pressure settings are maintained.

Data centers and bitcoin mining site has varieties of situations. Different scale/electrical infrastructure/space/redundancy/etc determine the size of SCS. The customized SCS will make the cost per coldplate in pumping systems be kept to a minimum and the redundancy be kept high.

For N series, we also use skid mounted technology to build smart control system.

Remote Monitor & Control Platform

Sanitary Stainless Steel Pipe Syste

Deionized water (DI water), due to its extremely low ion content, actively dissolves metal ions, accelerating corrosion over time.

Standard industrial stainless steel pipes often have a rough surface, which can release Fe, Cr, and Ni ions into the water. This contamination not only degrades water quality but can also clog the microchannels of cold plates, ultimately reducing heat exchange efficiency.

In contrast, sanitary-grade stainless steel features exceptionally low ion dissolution, ensuring long-term purity of the coolant. This helps prevent corrosion of cold plates and heat exchangers, maintaining optimal performance and reliability.

All-in-One Design

Stainless Steel Dripless Quick Disconnectors

Quick Disconnects (QDs) with flush-face connectors are essential in Direct Liquid Cooling systems. They enable fast, hot-swappable server maintenance while ensuring the structural integrity required by data centers. With minimal fluid loss during disconnection (reduced to a surface mist), QDs allow for flexible and efficient server configurations within racks.

Extreme Power Density

Thanks to the in-depth cooperation with MicroBT, We were able to launch the highest power density containerised solution.

The 20 feet container's maximum power is up to 1.6MW; whereas the 40 feet container's maximum power is up to 3.6MW.

High power density brings a lot of advantages.

- Save space

- Save electrical infrastructure investment

- Improve energy efficiency, reduce PUE

- Save deployment cost and time

- Save O&M cost

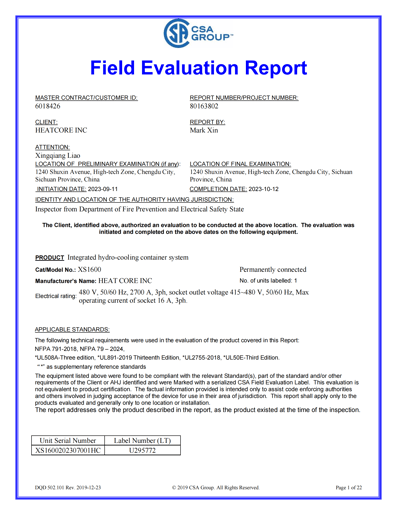

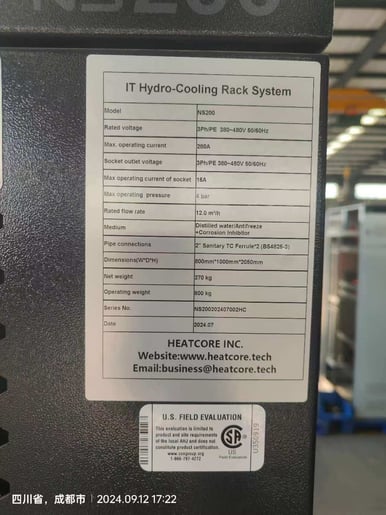

CSA Field Evaluation & CE certificated

Our systems feature the CSA mark, widely recognized by jurisdictions across North America, simplifying the process of passing field inspections and ensuring a smoother approval workflow.

Moreover, the entire system is CE-certified and fully compliant with EN 60204-1, making it suitable for deployment in Europe and other regions outside North America. This dual certification ensures your system meets strict regulatory requirements across multiple markets, providing both flexibility and peace of mind.

Our systems feature the CSA mark, widely recognized by jurisdictions across North America, simplifying the process of passing field inspections and ensuring a smoother approval workflow.

Moreover, the entire system is CE-certified and fully compliant with EN 60204-1, making it suitable for deployment in Europe and other regions outside North America. This dual certification ensures your system meets strict regulatory requirements across multiple markets, providing both flexibility and peace of mind.

Customized Modular Solution for

HEATING PROJECT

We provide customized heating solutions, leveraging modular designs to deliver complete project plans in under a week and production within 6 weeks.

.jpg?width=2000&name=dc(1).jpg)

Zero Water Consumption Cooling

Direct Liquid Cooling

Direct Liquid Cooling (DLC) works by circulating a liquid coolant—such as water or non-conductive fluids through specially designed cold plates or heat sinks that are in direct contact with the hardware. The liquid absorbs the heat and carries it away to an external heat exchanger or dry cooler, where it is dissipated into the environment or repurposed for secondary uses, such as heating nearby facilities. This method is far more efficient than air cooling, offering higher thermal conductivity, lower energy consumption, and a significantly reduced carbon footprint.

This results in much higher rack density, high PUE(<1.03) and allowing compact system designs without compromising performance. DLC’s ability to reclaim and reuse waste heat further enhances energy efficiency, making it an ideal solution for sustainable, high-performance operations like data centers and bitcoin mining.

Customized smart control system(SCS)

Data centers uses standard CDU(Coolant Distribution Units, in Heat Core we call it Smart Control System). It loses flexibility. The Coolant Distribution Units (CDU) use the Smart Control System to intelligently manage the centralized pumping system that cools multiple racks and ensures target flow and pressure settings are maintained.

Data centers and bitcoin mining site has varieties of situations. Different scale/electrical infrastructure/space/redundancy/etc determine the size of SCS. The customized SCS will make the cost per coldplate in pumping systems be kept to a minimum and the redundancy be kept high.

For N series, we also use skid mounted technology to build smart control system.

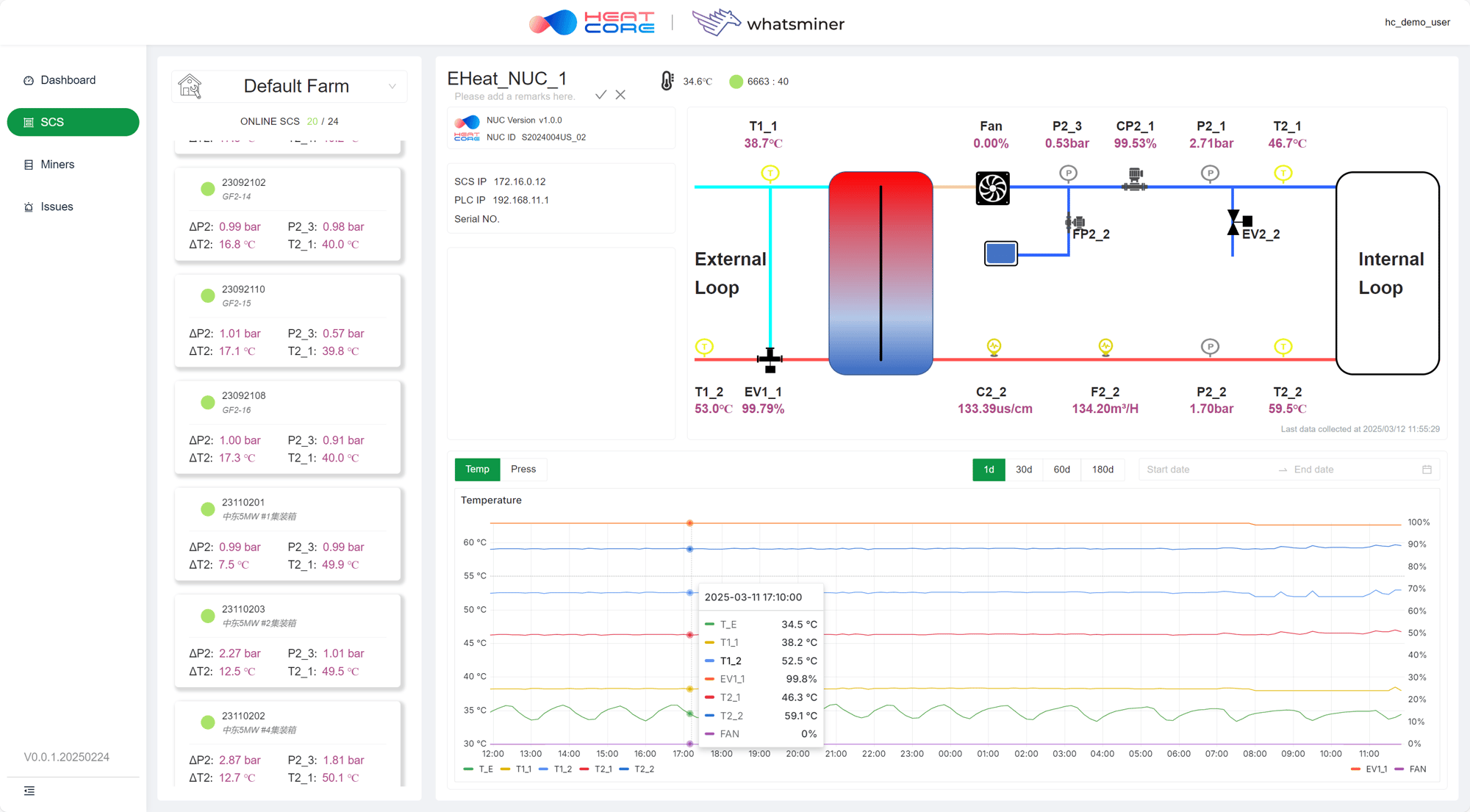

Remote monitor and control platform

Rather than just offering hardware, we focus on delivering comprehensive solutions to our users.

Our cloud-based remote control and monitoring platform is built on Amazon Web Services (AWS) servers in the United States, leveraging AWS's robust security and compliance standards to ensure data protection.

This platform enables real-time monitoring and control of both cooling systems and bitcoin miners. It not only empowers users to efficiently manage their systems but also allows our engineers to quickly identify and resolve issues, minimizing downtime.

Currently, this service is provided free of charge to all our users.

Sanitary Stainless Steel Pipe System

Deionized water (DI water), due to its extremely low ion content, actively dissolves metal ions, accelerating corrosion over time.

Standard industrial stainless steel pipes often have a rough surface, which can release Fe, Cr, and Ni ions into the water. This contamination not only degrades water quality but can also clog the microchannels of cold plates, ultimately reducing heat exchange efficiency.

In contrast, sanitary-grade stainless steel features exceptionally low ion dissolution, ensuring long-term purity of the coolant. This helps prevent corrosion of cold plates and heat exchangers, maintaining optimal performance and reliability.

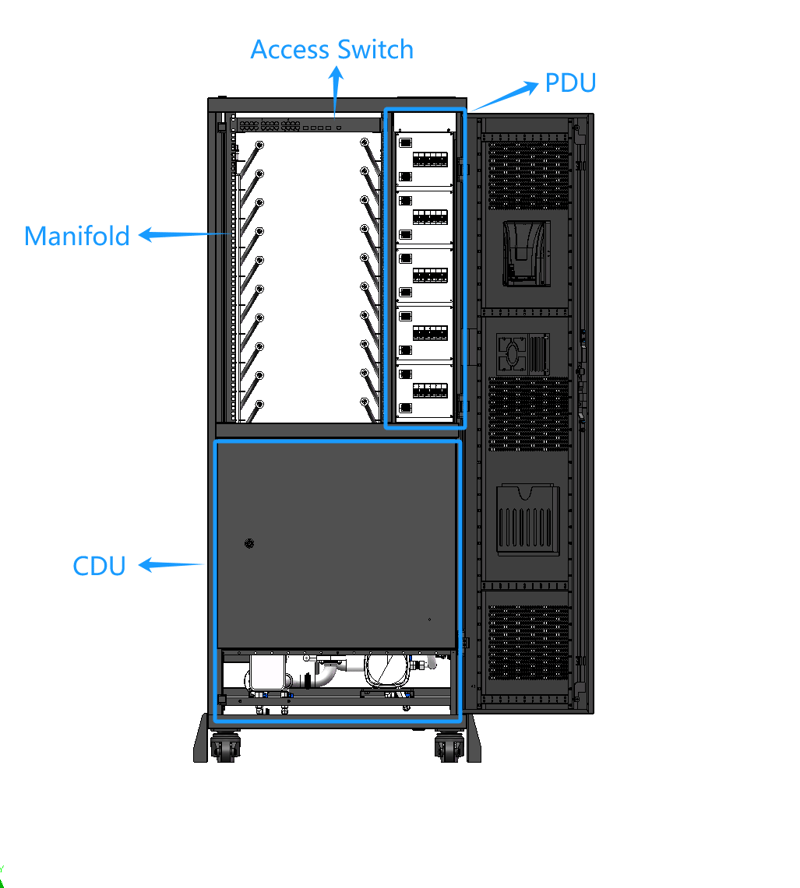

All-in-One Design

Our engineers always consider to make the deploy work fast and easy.

Each rack integrates a Power Distribution Unit, unmanaged network switches (access layer), and in/out manifolds. For X and E series, we’ve also included a main power switchboard and smart control system. These highly integrated units significantly simplify installation and deployment, reducing workload and time.

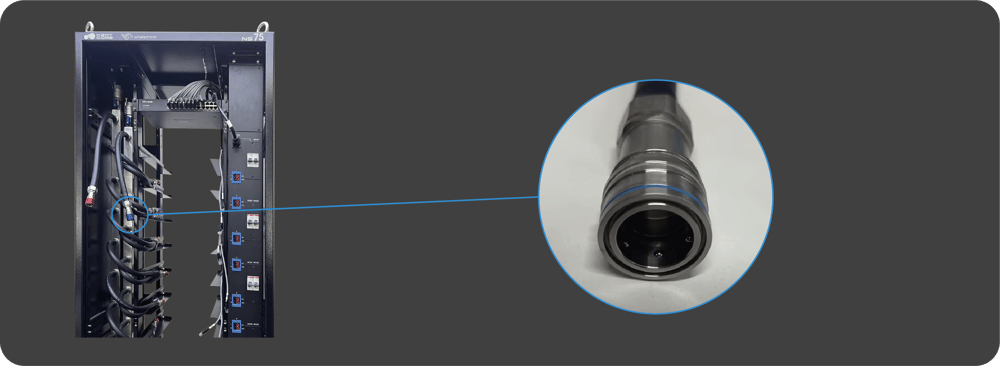

Stainless Steel Dripless Quick Disconnectors

Quick Disconnects (QDs) with flush-face connectors are essential in Direct Liquid Cooling systems. They enable fast, hot-swappable server maintenance while ensuring the structural integrity required by data centers. With minimal fluid loss during disconnection (reduced to a surface mist), QDs allow for flexible and efficient server configurations within racks.

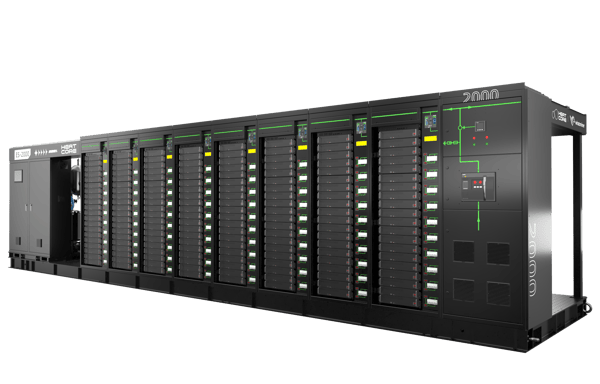

Extreme Power Density

Thanks to the in-depth cooperation with MicroBT, We were able to launch the highest power density containerised solution.

The 20 feet container's maximum power is up to 1.6MW; whereas the 40 feet container's maximum power is up to 3.6MW.

High power density brings a lot of advantages.

- Save space

- Save electrical infrastructure investment

- Improve energy efficiency, reduce PUE

- Save deployment cost and time

- Save O&M cost

CSA Field Evaluation/CE certificated

Unlike standard component certifications, we provide comprehensive system certifications that ensure full compliance with the National Electrical Code (NFPA 70) in the United States and the Canadian Electrical Code (CSA C22.2) in Canada. This includes Field Evaluations in the U.S. and Special Inspections in Canada.

Our systems feature the CSA mark, widely recognized by jurisdictions across North America, simplifying the process of passing field inspections and ensuring a smoother approval workflow.

Moreover, the entire system is CE-certified and fully compliant with EN 60204-1, making it suitable for deployment in Europe and other regions outside North America. This dual certification ensures your system meets strict regulatory requirements across multiple markets, providing both flexibility and peace of mind.

Customized Modular Solution for Heating Project

Zero Water Consumption Cooling

-

-

Direct Liquid Cooling

-

Customized Smart Control System (SCS)

-

Remote Monitor & Control Platform

-

304 Stainless Steel System

-

All-In-One Design

-

Water-Electricity Isolation

-

Skid-Mounted Solution

-

Stainless Steel Dripless Quick Disconnectors

-

Extreme Power Density

-

CSA Field Evaluation/CE Certificated

-

Customized Modular Solution For Heating Project

-

Zero Water Consumption Cooling

Cold-Plate Direct Liquid Cooling

Cold-Plate Direct Liquid Cooling (DLC) works by circulating a liquid coolant—such as water or non-conductive fluids through specially designed cold plates or heat sinks that are in direct contact with the hardware. The liquid absorbs the heat and carries it away to an external heat exchanger or dry cooler, where the heat is dissipated into the environment or repurposed for secondary uses, such as heating nearby facilities. This method is far more efficient than air cooling, offering higher thermal conductivity, lower energy consumption, and a significantly reduced carbon footprint.

This results in much higher rack density, ultra-low PUE (<1.03), while allowing compact system designs without compromising performance. DLC’s ability to reclaim and reuse waste heat further enhances energy efficiency, making it an ideal solution for sustainable, high-performance operations like data centers and bitcoin mining.

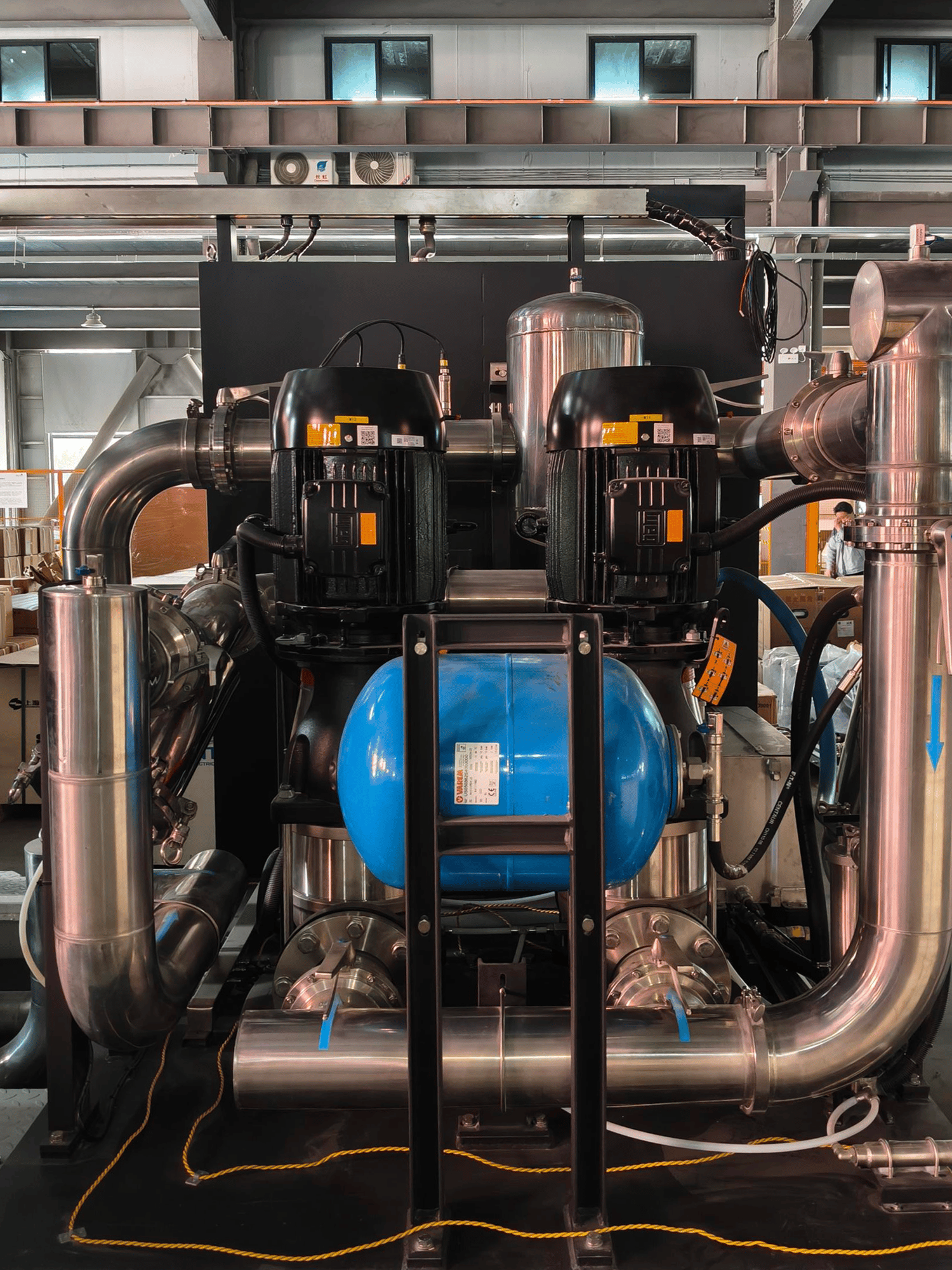

Customized Smart Control System (SCS)

Data centers uses standard Coolant Distribution Units(CDUs), which often lack flexibility. In contrast, HeatCore's Smart Control System(SCS) intelligently manages the centralized pumping system to cool multiple racks while maintaining optimal flow and pressure settings. It also monitors and controls server paratemeters, such as temperature and performance, ensuring efficient operation.

Data centers and bitcoin mining site face diverse situations. Different scale/electrical infrastructure/space/redundancy/etc determine the size of SCS. The customized SCS minimizes the cost per coldplate in pumping systems while maintaining high redundancy for reliable performance.

For the N series, we employ skid-mounted technology to build smart control system, enabling modular and scalable cooling solutions tailored to specific needs.

Remote Monitor & Control Platform

Rather than just offering hardware, we focus on delivering comprehensive solutions to our users.

Our cloud-based remote control and monitoring platform is built on Amazon Web Services (AWS) servers in the United States, leveraging AWS's robust security and compliance standards to ensure data protection.

This platform enables real-time monitoring and control of both cooling systems and bitcoin miners, serving as an essential tool for achieving unattended or minimally staffed operations. It not only empowers users to efficiently manage their systems but also allows our engineers to quickly identify and resolve issues, minimizing downtime.

Currently, this service is provided at no additional cost to all users.

304 Stainless Steel System

Deionized water (DI water), due to its extremely low ion content, actively dissolves metal ions, accelerating corrosion over time.

Standard industrial stainless steel pipes often have a rough surface, which can release Fe, Cr, and Ni ions into the water. This contamination not only degrades water quality but can also clog the microchannels of cold plates, ultimately reducing heat exchange efficiency.

In contrast, sanitary-grade stainless steel features exceptionally low ion dissolution, ensuring long-term purity of the coolant. This helps prevent corrosion of cold plates and heat exchangers, maintaining optimal performance and reliability.

All-In-One Design

Our engineers always consider to make the deploy work fast and easy.

Each rack integrates a Power Distribution Unit, unmanaged network switches (access layer), and in/out manifolds. For X and E series, we’ve also included a main power switchboard and Smart Control System. These highly integrated units significantly simplify installation and deployment, reducing workload and time.

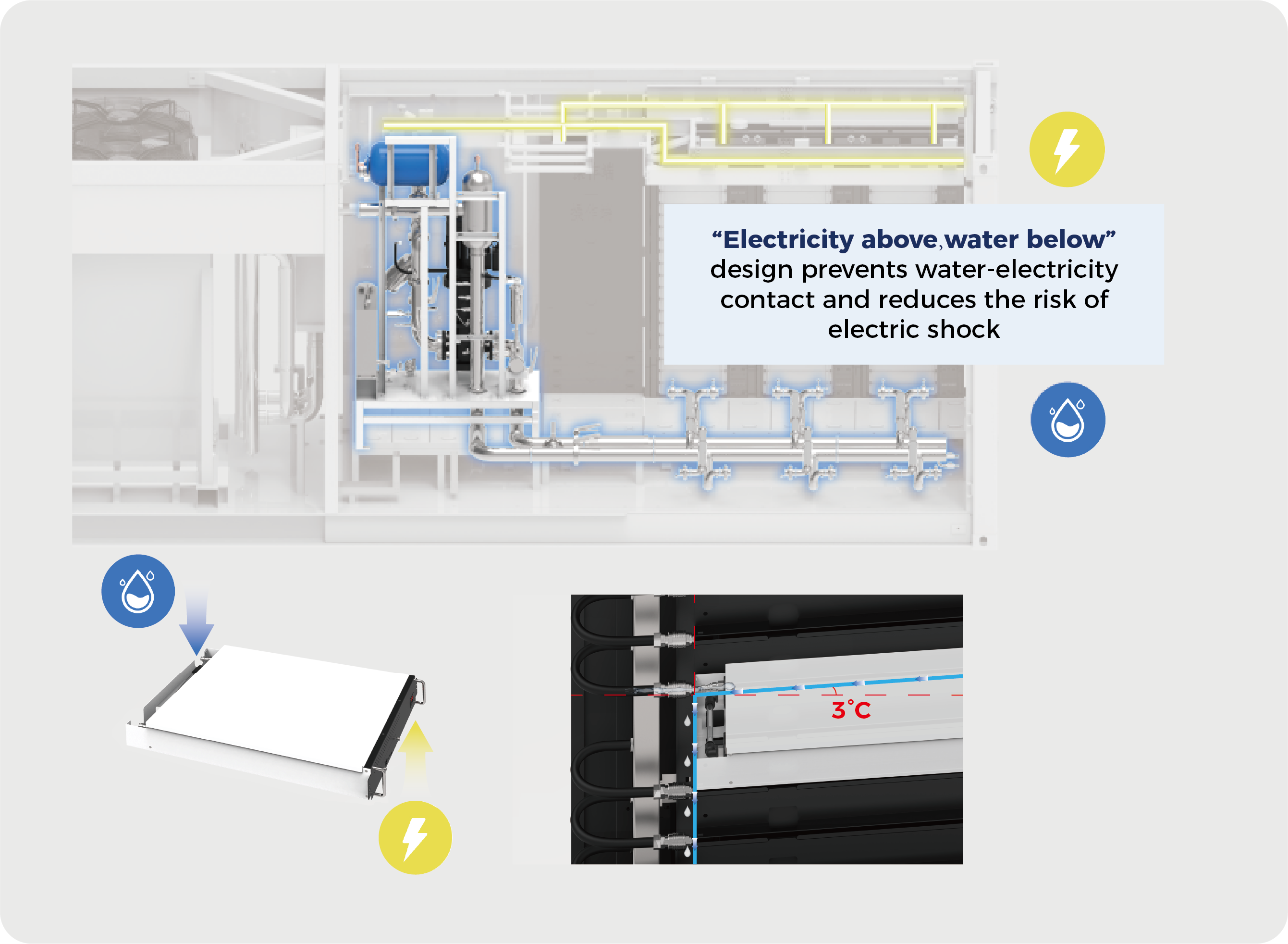

Water-Electricity Isolation

Our system features a unique water-electricity isolation design: the power and network interfaces are positioned on one side, while the water inlet and outlet are placed on the opposite side. Also, the copper busbar is installed above the N-Rack, maintaining a clear vertical distance from the water pipes located beneath the racks. This physical separation significantly reduces the risk of contact between electrical and water systems.

In addition, compared to the conventional horizontal 2U rack, there is a 3° tilt drainage design in each slot, preventing the electrical fault or damage brought by fluid leakage.

Skid-Mounted Solution

Skid-mounted system are designed for indoor deployment and are pre-assembled pieces of equipment or a process system mounted on a sturdy frame, typically made of steel, for easy transportation and installation. This modular approach allows for off-site fabrication and testing, minimising on-site work and disruption.

We incorporate the skid-mounted approach throughout our designs—our E Series and most large-scale Smart Control Systems.These designs streamline deployment and enhance system reliability.

Stainless Steel Dripless Quick Disconnectors

Quick Disconnectors (QDs) with flush-face connectors are essential for Direct Liquid Cooling systems. They enable rapid, hot-swappable server maintenance while ensuring the structural integrity required by data centers. With minimal fluid loss during disconnection (reduced to a surface mist), QDs support for flexible and efficient server configurations within racks.

By default, the female Disconnectors are included and pre installed in HeatCore's system.

Extreme Power Density

Thanks to the in-depth cooperation with MicroBT, we were able to launch the highest power density containerised solution.

The 20 feet-20 HQ container's maximum power is up to 1.6MW; whereas the 40 feet-40HQ container's maximum power is up to 3.6MW.

High power density brings a lot of advantages.

- Save space

- Save electrical infrastructure investment

- Improve energy efficiency and reduce PUE

- Save deployment cost and time

- Save O&M cost

CSA Field Evaluation/CE Certificated

Unlike standard component certifications, we provide comprehensive system certifications that ensure compliance with UL standards, the National Electrical Code (NFPA 70) in the United States, and the Canadian Electrical Code (CSA C22.2) in Canada. This includes Field Evaluations in the U.S. and Special Inspections in Canada.

Our products feature the CSA mark, widely recognized by jurisdictions across North America, streamlining field inspections and approvals.

Moreover, the entire system is CE-certified and fully compliant with EN 60204-1, making it suitable for deployment in Europe and other regions outside North America. This dual certification ensures your system meets strict regulatory requirements across multiple markets, providing both flexibility and peace of mind.

Customized Modular Solution For Heating Project

We provide customized heating solutions, leveraging modular designs to deliver complete project plans in under a week and production within 6 weeks.

Zero Water Consumption Cooling

All of our solution is based on dry cooler. ensuring zero water waste, lower O&M costs, and reduced TCO(Total Cost of Ownership).

DIRECT LIQUID COOLING

Direct Liquid Cooling (DLC) works by circulating a liquid coolant—such as water or non-conductive fluids through specially designed cold plates or heat sinks that are in direct contact with the hardware. The liquid absorbs the heat and carries it away to an external heat exchanger or dry cooler, where it is dissipated into the environment or repurposed for secondary uses, such as heating nearby facilities. This method is far more efficient than air cooling, offering higher thermal conductivity, lower energy consumption, and a significantly reduced carbon footprint.

This results in much higher rack density, high PUE(<1.03) and allowing compact system designs without compromising performance. DLC’s ability to reclaim and reuse waste heat further enhances energy efficiency, making it an ideal solution for sustainable, high-performance operations like data centers and bitcoin mining.

CUSTOMIZED SMART CONTROL SYSTEM (SCS)

Data centers uses standard CDU(Coolant Distribution Units, in Heat Core we call it Smart Control System). It loses flexibility. The Coolant Distribution Units (CDU) use the Smart Control System to intelligently manage the centralized pumping system that cools multiple racks and ensures target flow and pressure settings are maintained.

Data centers and bitcoin mining site has varieties of situations. Different scale/electrical infrastructure/space/redundancy/etc determine the size of SCS. The customized SCS will make the cost per coldplate in pumping systems be kept to a minimum and the redundancy be kept high.

For N series, we also use skid mounted technology to build smart control system.

REMOTE MONITOR & CONTROL PLATFORM

Rather than just offering hardware, we focus on delivering comprehensive solutions to our users.

Our cloud-based remote control and monitoring platform is built on Amazon Web Services (AWS) servers in the United States, leveraging AWS's robust security and compliance standards to ensure data protection.

This platform enables real-time monitoring and control of both cooling systems and bitcoin miners. It not only empowers users to efficiently manage their systems but also allows our engineers to quickly identify and resolve issues, minimizing downtime.

Currently, this service is provided free of charge to all our users.

SANITARY STAINLESS STEEL PIPE SYSTEM

Deionized water (DI water), due to its extremely low ion content, actively dissolves metal ions, accelerating corrosion over time.

Standard industrial stainless steel pipes often have a rough surface, which can release Fe, Cr, and Ni ions into the water. This contamination not only degrades water quality but can also clog the microchannels of cold plates, ultimately reducing heat exchange efficiency.

In contrast, sanitary-grade stainless steel features exceptionally low ion dissolution, ensuring long-term purity of the coolant. This helps prevent corrosion of cold plates and heat exchangers, maintaining optimal performance and reliability.

ALL-IN-ONE DESIGN

Our engineers always consider to make the deploy work fast and easy.

Each rack integrates a Power Distribution Unit, unmanaged network switches (access layer), and in/out manifolds. For X and E series, we’ve also included a main power switchboard and smart control system. These highly integrated units significantly simplify installation and deployment, reducing workload and time.

STAINLESS STEEL DRIPLESS QUICK DISCONNECTORS

Quick Disconnects (QDs) with flush-face connectors are essential in Direct Liquid Cooling systems. They enable fast, hot-swappable server maintenance while ensuring the structural integrity required by data centers. With minimal fluid loss during disconnection (reduced to a surface mist), QDs allow for flexible and efficient server configurations within racks.

EXTREME POWER DENSITY

Thanks to the in-depth cooperation with MicroBT, We were able to launch the highest power density containerised solution.

The 20 feet container's maximum power is up to 1.6MW; whereas the 40 feet container's maximum power is up to 3.6MW.

High power density brings a lot of advantages.

- Save space

- Save electrical infrastructure investment

- Improve energy efficiency, reduce PUE

- Save deployment cost and time

- Save O&M cost

CSA FIELD EVALUATION/CE CERTIFICATED

Unlike standard component certifications, we provide comprehensive system certifications that ensure full compliance with the National Electrical Code (NFPA 70) in the United States and the Canadian Electrical Code (CSA C22.2) in Canada. This includes Field Evaluations in the U.S. and Special Inspections in Canada.

Our systems feature the CSA mark, widely recognized by jurisdictions across North America, simplifying the process of passing field inspections and ensuring a smoother approval workflow.

Moreover, the entire system is CE-certified and fully compliant with EN 60204-1, making it suitable for deployment in Europe and other regions outside North America. This dual certification ensures your system meets strict regulatory requirements across multiple markets, providing both flexibility and peace of mind.

CUSTOMIZED MODULAR SOLUTION FOR HEATING PROJECT

We provide customized heating solutions, leveraging modular designs to deliver complete project plans in under a week and production within 6 weeks.

ZERO WATER CONSUMPTION COOLING

All of our solution is based on dry cooler. ensuring zero water waste, lower O&M costs, and reduced Total Ownership Cost (TOC).

-

Technology

-

Direct Liquid Cooling

-

Sanitary Stainless Steel Pipe System

-

Remote Monitor & Control Platform

-

Sanitary Stainless Steel Pipe Syste

-

All-in-One Design

-

Stainless Steel Dripless Quick Disconnectors

-

Extreme Power Density

-

CSA Field Evaluation & CE certificated

-

Customized Modular Solution for Heating Project

-

Zero Water Consumption Cooling

Direct Liquid Cooling

Direct Liquid Cooling (DLC) works by circulating a liquid coolant—such as water or non-conductive fluids through specially designed cold plates or heat sinks that are in direct contact with the hardware. The liquid absorbs the heat and carries it away to an external heat exchanger or dry cooler, where it is dissipated into the environment or

repurposed for secondary uses, such as heating nearby facilities. This method is far more efficient than air cooling, offering higher thermal conductivity, lower energy consumption, and a significantly reduced carbon footprint.

This results in much higher rack density, high PUE(<1.03) and allowing compact system designs without com

promising performance.

Sanitary Stainless Steel Pipe System

Data centers uses standard CDU(Coolant Distribution Units, in Heat Core we call it Smart Control System). It loses flexibility. The Coolant Distribution Units (CDU) use the Smart Control System to intelligently manage the centralized pumping system that cools multiple racks and ensures target flow and pressure settings are maintained.

Data centers and bitcoin mining site has varieties of situations. Different scale/electrical infrastructure/space/redundancy/etc determine the size of SCS. The customized SCS will make the cost per coldplate in pumping systems be kept to a minimum and the redundancy be kept high.

For N series, we also use skid mounted technology to build smart control system.

Remote Monitor & Control Platform

Rather than just offering hardware, we focus on delivering comprehensive solutions to our users.Our cloud-based remote control and monitoring platform is built on Amazon Web Services (AWS) servers in the United States, leveraging AWS's robust security and compliance standards to ensure data protection.This platform enables real-time monitoring and control of both cooling systems and bitcoin miners. It not only empowers users to efficiently manage their systems but also allows our engineers to quickly identify and resolve issues, minimizing downtime.Currently, this service is provided free of charge to all our users.

Sanitary Stainless Steel Pipe Syste

Deionized water (DI water), due to its extremely low ion content, actively dissolves metal ions, accelerating corrosion over time.

Standard industrial stainless steel pipes often have a rough surface, which can release Fe, Cr, and Ni ions into the water. This contamination not only degrades water quality but can also clog the microchannels of cold plates, ultimately reducing heat exchange efficiency.

In contrast, sanitary-grade stainless steel features exceptionally low ion dissolution, ensuring long-term purity of the coolant. This helps prevent corrosion of cold plates and heat exchangers, maintaining optimal performance and reliability.

All-in-One Design

Our engineers always consider to make the deploy work fast and easy.Each rack integrates a Power Distribution Unit, unmanaged network switches (access layer), and in/out manifolds. For X and E series, we’ve also included a main power switchboard and smart control system. These highly integrated units significantly simplify installation and deployment, reducing workload and time.

Stainless Steel Dripless Quick Disconnectors

Quick Disconnects (QDs) with flush-face connectors are essential in Direct Liquid Cooling systems. They enable fast, hot-swappable server maintenance while ensuring the structural integrity required by data centers. With minimal fluid loss during disconnection (reduced to a surface mist), QDs allow for flexible and efficient server configurations within racks.

Extreme Power Density

Thanks to the in-depth cooperation with MicroBT, We were able to launch the highest power density containerised solution.

The 20 feet container's maximum power is up to 1.6MW; whereas the 40 feet container's maximum power is up to 3.6MW.

High power density brings a lot of advantages.

- Save space

- Save electrical infrastructure investment

- Improve energy efficiency, reduce PUE

- Save deployment cost and time

- Save O&M cost

CSA Field Evaluation & CE certificated

Unlike standard component certifications, we provide comprehensive system certifications that ensure full compliance with the National Electrical Code (NFPA 70) in the United States and the Canadian Electrical Code (CSA C22.2) in Canada. This includes Field Evaluations in the U.S. and Special Inspections in Canada.

Our systems feature the CSA mark, widely recognized by jurisdictions across North America, simplifying the process of passing field inspections and ensuring a smoother approval workflow.

Moreover, the entire system is CE-certified and fully compliant with EN 60204-1, making it suitable for deployment in Europe and other regions outside North America. This dual certification ensures your system meets strict regulatory requirements across multiple markets, providing both flexibility and peace of mind.

Customized Modular Solution for Heating Project

We provide customized heating solutions, leveraging modular designs to deliver complete project plans in under a week and production within 6 weeks.

Zero Water Consumption Cooling

All of our solution is based on dry cooler. ensuring zero water waste, lower O&M costs, and reduced Total Ownership Cost (TOC)..jpg?width=4267&height=3200&name=dc(1).jpg)

-

Technology

-

Direct Liquid Cooling

-

Sanitary Stainless Steel Pipe System

-

Remote Monitor & Control Platform

-

Sanitary Stainless Steel Pipe Syste

-

All-in-One Design

-

Stainless Steel Dripless Quick Disconnectors

-

Extreme Power Density

-

CSA Field Evaluation & CE certificated

-

Customized Modular Solution for Heating Project

-

Zero Water Consumption Cooling

Direct Liquid Cooling

Direct Liquid Cooling (DLC) works by circulating a liquid coolant—such as water or non-conductive fluids through specially designed cold plates or heat sinks that are in direct contact with the hardware. The liquid absorbs the heat and carries it away to an external heat exchanger or dry cooler, where it is dissipated into the environment or

repurposed for secondary uses, such as heating nearby facilities. This method is far more efficient than air cooling, offering higher thermal conductivity, lower energy consumption, and a significantly reduced carbon footprint.

This results in much higher rack density, high PUE(<1.03) and allowing compact system designs without com

promising performance.

Sanitary Stainless Steel Pipe System

Data centers uses standard CDU(Coolant Distribution Units, in Heat Core we call it Smart Control System). It loses flexibility. The Coolant Distribution Units (CDU) use the Smart Control System to intelligently manage the centralized pumping system that cools multiple racks and ensures target flow and pressure settings are maintained.

Data centers and bitcoin mining site has varieties of situations. Different scale/electrical infrastructure/space/redundancy/etc determine the size of SCS. The customized SCS will make the cost per coldplate in pumping systems be kept to a minimum and the redundancy be kept high.

For N series, we also use skid mounted technology to build smart control system.

Remote Monitor & Control Platform

Rather than just offering hardware, we focus on delivering comprehensive solutions to our users.Our cloud-based remote control and monitoring platform is built on Amazon Web Services (AWS) servers in the United States, leveraging AWS's robust security and compliance standards to ensure data protection.This platform enables real-time monitoring and control of both cooling systems and bitcoin miners. It not only empowers users to efficiently manage their systems but also allows our engineers to quickly identify and resolve issues, minimizing downtime.Currently, this service is provided free of charge to all our users.

Sanitary Stainless Steel Pipe Syste

Deionized water (DI water), due to its extremely low ion content, actively dissolves metal ions, accelerating corrosion over time.

Standard industrial stainless steel pipes often have a rough surface, which can release Fe, Cr, and Ni ions into the water. This contamination not only degrades water quality but can also clog the microchannels of cold plates, ultimately reducing heat exchange efficiency.

In contrast, sanitary-grade stainless steel features exceptionally low ion dissolution, ensuring long-term purity of the coolant. This helps prevent corrosion of cold plates and heat exchangers, maintaining optimal performance and reliability.

All-in-One Design

Our engineers always consider to make the deploy work fast and easy.Each rack integrates a Power Distribution Unit, unmanaged network switches (access layer), and in/out manifolds. For X and E series, we’ve also included a main power switchboard and smart control system. These highly integrated units significantly simplify installation and deployment, reducing workload and time.

Stainless Steel Dripless Quick Disconnectors

Quick Disconnects (QDs) with flush-face connectors are essential in Direct Liquid Cooling systems. They enable fast, hot-swappable server maintenance while ensuring the structural integrity required by data centers. With minimal fluid loss during disconnection (reduced to a surface mist), QDs allow for flexible and efficient server configurations within racks.

Extreme Power Density

Thanks to the in-depth cooperation with MicroBT, We were able to launch the highest power density containerised solution.

The 20 feet container's maximum power is up to 1.6MW; whereas the 40 feet container's maximum power is up to 3.6MW.

High power density brings a lot of advantages.

- Save space

- Save electrical infrastructure investment

- Improve energy efficiency, reduce PUE

- Save deployment cost and time

- Save O&M cost

CSA Field Evaluation & CE certificated

Unlike standard component certifications, we provide comprehensive system certifications that ensure full compliance with the National Electrical Code (NFPA 70) in the United States and the Canadian Electrical Code (CSA C22.2) in Canada. This includes Field Evaluations in the U.S. and Special Inspections in Canada.

Our systems feature the CSA mark, widely recognized by jurisdictions across North America, simplifying the process of passing field inspections and ensuring a smoother approval workflow.

Moreover, the entire system is CE-certified and fully compliant with EN 60204-1, making it suitable for deployment in Europe and other regions outside North America. This dual certification ensures your system meets strict regulatory requirements across multiple markets, providing both flexibility and peace of mind.

Customized Modular Solution for Heating Project

We provide customized heating solutions, leveraging modular designs to deliver complete project plans in under a week and production within 6 weeks.

Zero Water Consumption Cooling

All of our solution is based on dry cooler. ensuring zero water waste, lower O&M costs, and reduced Total Ownership Cost (TOC)..jpg?width=4267&height=3200&name=dc(1).jpg)